Diamond Drag Engraver, Spring Loaded, 1/2 Shank x 120 Degree

Click Image for Gallery

Diamond Drag Engraver, Spring Loaded, 1/2" Shank x 120 Degree

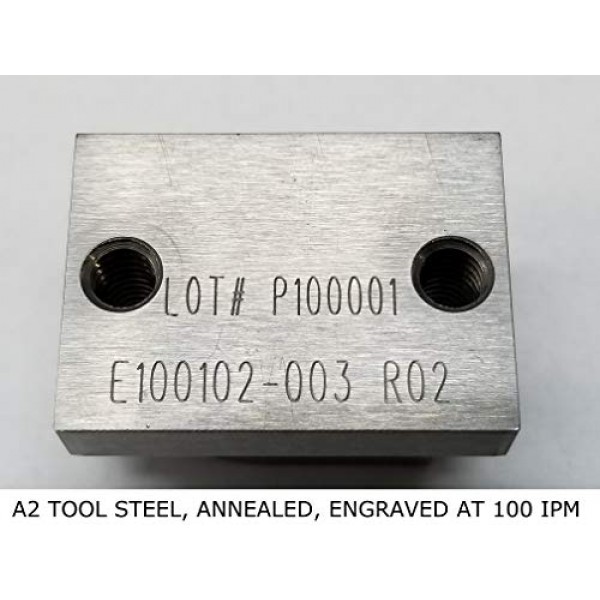

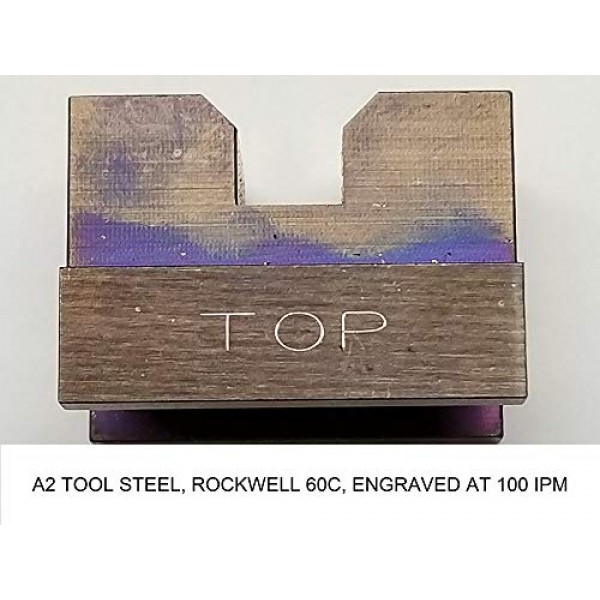

Spring loaded sliding diamond tip drag engraver can engrave on most substantially stiff materials from plastics to metals and glass-like materials. Extensive engraving on glass-like materials will tend to wear out the diamond tip quicker than for metals. To use, install into a 1/2" collet on your milling machine spindle or router, engage the diamond tip to the material and then move the spindle an additional 1/8" closer to the material. Doing so compresses the preload spring ensuring the diamond tip is in constant contact with the surface being engraved. Next run your CNC engraving program with the spindle off. Because the diamond tip is telescoping uneven surfaces are evenly engraved eliminating faded characters or over engraved characters. We have engraved hardened steel at 100 ipm! (see our YouTube video under Exact Engineering, LLC). Cutting engravers cannot compete! We recommend the stiff spring for metals and hard plastics and the soft spring for glass-like materials and a starting compression of 1/8". The engraving groove width/depth can be tailored by simply by changing the amount of tip compression and or spring or both. Proudly engineered and made in the USA!- Spring loaded diamond tip will engrave on uneven surfaces. Tip travel up to 0.30".

- Made from precision ground 0.4995-0.5000 diameter rod hardness of 35Rc for longevity. Can be used in end mill holders and collets.

- Corrosion resistant 17-4SS 35 Rc body and 300SS diamond engraver shank.

- Easily engrave on soft materials to full hard tools steels at feed rates of 100 ipm.

- Adjustable tip preload force. Includes 2 springs for differing materials. Engineered and Made in USA!